Challenge: At Haglid Engineering & Associates, Inc.®, we’re passionate about coming up with sound, creative solutions for a vast array of engineering projects. After all, variety is the spice of life and we do enjoy challenges! Although … we never thought we would be asked to bring The Louvre to Saddle River, New Jersey—part of it, anyway.

Let’s just say, architectural engineering can be fun!

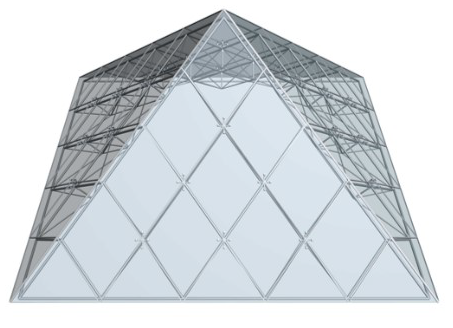

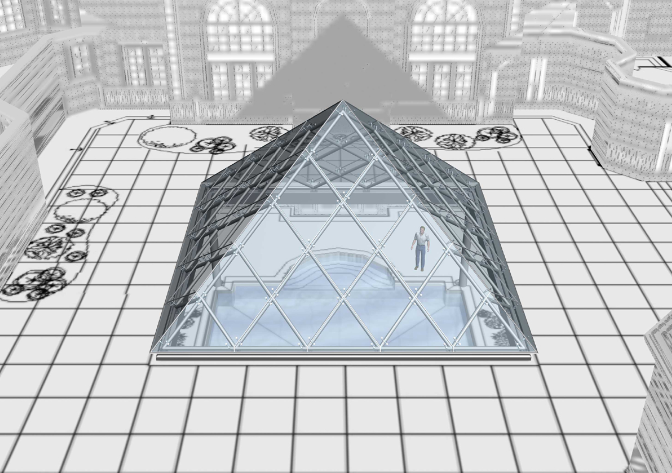

The 30-foot-high glass pyramid, a stunning skylight for this impressive home, sits eighteen feet above an indoor pool, surrounded by a 76-foot-wide raised patio area. Of course, such a beautiful structure is only worth creating if the sight lines work from different locations as well as through the windows of the main house.

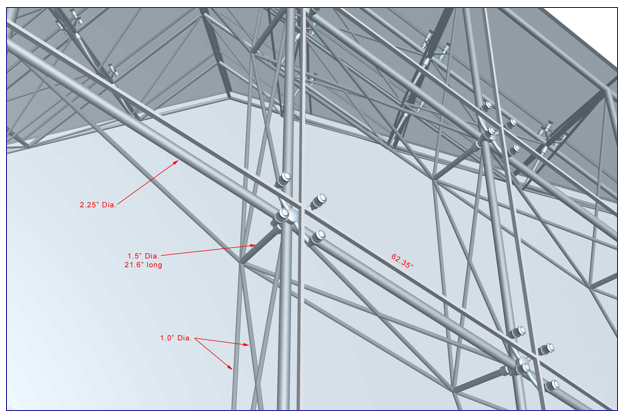

More important than aesthetics, the pyramid’s steel superstructure had to be stiff enough to support the glass while allowing for the thermal expansion and contraction metal and glass experience during temperature shifts. It was critical to analyze all these details via computer-generated 3-D modeling before construction began.

Solution:

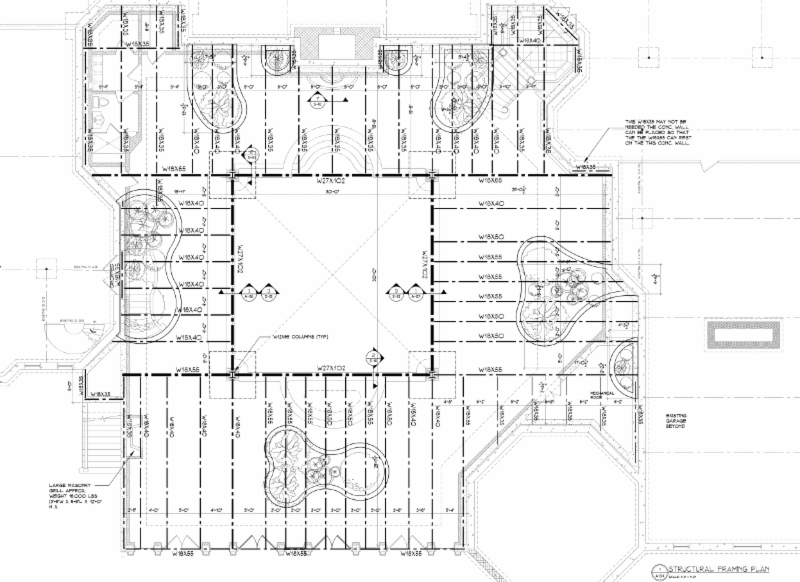

This diagram shows how Haglid Engineering & Associates, Inc.® provided the structural plans for lifting the massive glass pyramid 18 feet into the air over the pool. It can be noted that the steel superstructure had to be stiff enough to support the glass pyramid while allowing for thermal expansion and contraction due to cooling and heating from night to day. Every detail had to be analyzed and accounted for to enable the raised patio area to work with the pool below.

Through the use of computer generated 3-D modeling, the finished glass Louvre-type pyramid could be evaluated before it was built to achieve the desired lines of sight from different locations or through the windows of the main house.

For more information on achieving healthy, sustainable, energy-efficient HVAC, call Haglid Engineering at 201.722.1233.

Download Case Study